We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more

How to measure your gun for the correct size of lead ball

When shooting muzzle loading guns, the highest quality gear or most methodical of loading will be useless without the correct size ball. Given there is little standardisation to muzzle loading guns between manufacturers, and even less when concerning antique muzzle loaders, learning to establish the correct lead ball size is imperative to correct shooting. If you are shooting a modern muzzle loader, first consult the manufacturer's published loading data, this will give you the correct ball size for your gun. If not, carry on reading to learn more about how to measure your gun for the correct size of lead ball.

Measuring your muzzle loading revolver for ball size

Fortunately, muzzle loading revolvers are easy to measure, and there is lots of information published by the manufacturers regarding their loading.

Firstly, ensure the gun is unloaded. Next, remove the cylinder from the frame. This is accomplished on Colt open frame models by driving the wedge out, then pulling the barrel off the arbor, followed by the cylinder.

This is accomplished on Remington 1858 models by putting the gun on half cock, lowering the loading lever, and removing the cylinder pin, found above the hinge of the loading pin, then sliding the cylinder out to the right.

Secondly, take a set of calipers (preferably imperial, we sell a set that will measure in both imperial and metric, and measuring across the inside diameter of the cylinder, taking care to measure past the slight counterbore on the cylinder face. Move the calipers back and forth while retaining tension on the calipers. Measure all cylinders, you may find the cylinders are maybe a thousandth different, but this could as easily be human or caliper error, so take an average of all measurements.

For a .36 revolver, the correct size lead ball is usually .375, however, on this Pietta reproduction Colt model 1851, the cylinder measures out at .360 exactly, therefore, a .362 ball would be best.

The process is exactly the same for a .44 revolver, as can be seen on this Remington 1858, which measures at .440 in the cylinder, therefore would require a ball around .445

There is no exact science to finding the precisely correct size ball, so long as the ball is a few thousandths of an inch oversize, it can be swaged into the cylinder. I would not advise using a ball that is any more than .010 oversize, simply as it will be difficult to load.

Measuring your muzzle loading rifle for ball size.

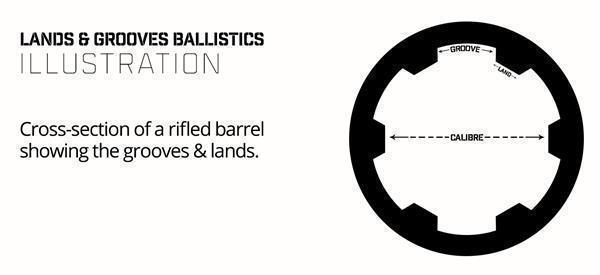

The process for measuring a muzzle loading rifle is very similar. Firstly, ensure the rifle is unloaded. Next, at the muzzle end, introduce the inside diameter calipers into the muzzle and measure the diameter between the lands. This may be difficult to see, use a torch or bore light if necessary to help you see the rifling.

A .45 muzzle loading hawken rifle, for example, usually measures about .450

Next, the thickness of patch should be deducted from the bore diameter. Therefore, if we take the bore diameter at .450, and plan on using a .010 patch, this sum will give the correct ball size:

450 - 010 = 440

Therefore, the correct ball size for this gun would be a .440 ball patched to .450.

Measuring for a musket is exactly the same as for a rifle, only there is no rifling to be aware of, so just the diameter of the bore at the muzzle is measured. The ball size for muskets is somewhat less important, as guns such as the Brown Bess were originally issued with balls considerably smaller than the bore diameter, for easier and faster loading in the field. Muskets can still be accurate weapons, so it still pays to measure and get the best fitting ball possible.

We stock a full range of muzzle loading accessories, including pre cast lead balls, and casting equipment and moulds of any size. Please also see our blog on using home-cast or pre-cast balls. For more information, please contact us on 0113 256 9163, or email [email protected]

Links to our products used in this post: