We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more

Damascus Folder

Article reproduced from Guns Review Magazine, September 1995.

As most readers will know, damascus steel is made by taking rods of different types of iron or steel and twisting them together, folding and forging them until the resultant bar has the different metals twisted and mixed in patterns which are often very beautiful. Damascus gun barrels were made by twisting the resulting bar around a mandrel and forging it into a tube. Damascus has been used in blades for centuries and has two special attributes. One is aesthetic. The patterns which can be created within the steel are often unique and artistic. Additionally, the various types of metal used have differing qualities. One will be very hard, and if used in isolation might be a little brittle and would certainly be difficult to sharpen. Another type might be very soft, more easily bent, and easily blunted. Twisting these steels together produces a blade in which hard and soft steels lie next to each other in fine, almost microscopic strands. Thus the hard and brittle strands cannot break and the softer strands cannot bend. The edge put on the soft metals is protected by the hard metal and the hard metal is easy to sharpen because it is sandwiched in very fine strands amongst soft metal. If the edge of a damascus blade were examined under a microscope, it would appear to have a slightly saw-tooth appearance because of the mixes of steel and this gives it a cutting ability which is quite amazing.

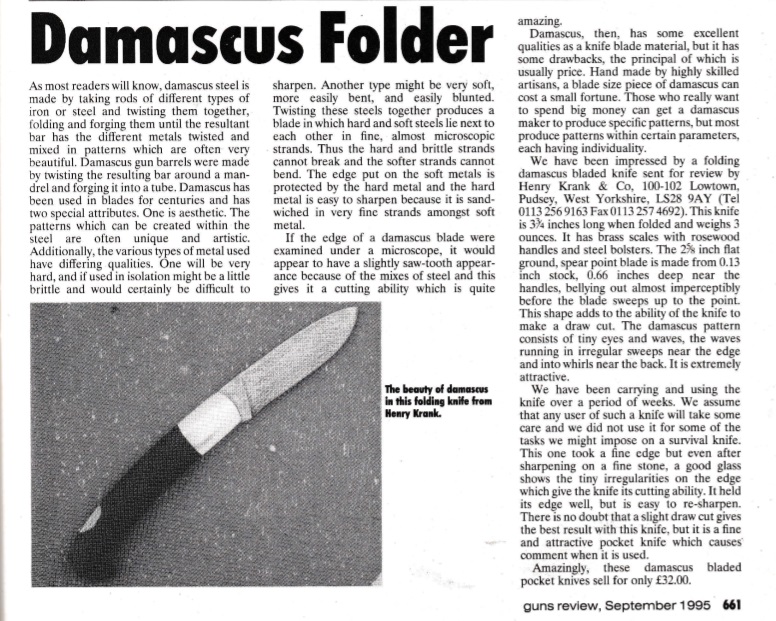

Damascus, then, has some excellent qualities as a knife blade material, but it has some drawbacks, the principal of which is usually price. Hand made by highly skilled artisans, a blade size piece of damascus can cost a small fortune. Those who really want to spend big money can get a damascus maker to produce specific patterns, but most produce patterns within certain parameters, each having individuality. We have been impressed by a folding damascus bladed knife sent for review by Henry Krank & Co. This knife is 3/+ inches long when folded and weighs 3 ounces. It has brass scales with rosewood handles and steel bolsters. The 2s's inch flat ground, spear point blade is made from 0.13 inch stock, 0.66 inches deep near the handles, bellying out almost imperceptibly before the blade sweeps up to the point. This shape adds to the ability of the knife to make a draw cut. The damascus pattern consists of tiny eyes and waves, the waves running in irregular sweeps near the edge and into whirls near the back. It is extremely attractive. We have been carrying and using the knife over a period of weeks. We assume that any user of such a knife will take some care and we did not use it for some of the tasks we might impose on a survival knife. This one took a fine edge but even after sharpening on a fine stone, a good glass shows the tiny irregularities on the edge which give the knife its cutting ability. It held its edge well, but is easy to re-sharpen. There is no doubt that a slight draw cut gives the best result with this knife, but it is a fine and attractive pocket knife which causes comment when it is used. Amazingly, these damascus bladed pocket knives sell for only £39.00.

To view the full range of damascus knives available to order online, click here.

This is a complete reproduction of the Guns Review article, September 1995. The views and opinions expressed in this article are those of the authors; Guns Review, Ravenhill Publishing, September 1995, and do not reflect those of Henry Krank & Co. Ltd and are reproduced here for entertainment purposes only. Henry Krank & Co. Ltd. shall not be held liable for any damage, injury, loss or detriment resulting from following the advice contained herein. Henry Krank & Co. Ltd. do not advocate following any of the advice here reproduced and urge anyone in any doubt to seek a professional opinion.